-

Wastewater Discharge Information Disclosure Sheet of Shaanxi The River Pharmaceutical Co.,Ltd.

1、 Basic information:Company name: Shaanxi Dahe Pharmaceutical Co., Lt.......

2023-01-16 -

The Senior Seminar on the Ability Improvement of the Deputy Division Cadres of the Food and Drug Regulatory System was successfully held in Zhejiang University

The Senior Seminar on the Ability Improvement of the Deputy Division C.......

2023-01-16

Shaanxi The River Pharmaceutical Co.,Ltd.

2019 Waste Water and Waste Gas Emission Information Disclosure Sheet

1、 Basic information:

Company name: Shaanxi Dahe Pharmaceutical Co., Ltd

Unified social credit code: 91610000737994855W

Legal representative: Wang Duqi

Production address: No. 3, Jingwei 10th Road, Jinghe Industrial Park, Gaoling District, Xi'an City, Shaanxi Province

Contact: 029-86067874

Industry category: manufacturing of chemical raw materials

Production and business scope and output: production, sales, import and export of raw materials (lappaconitine hydrobromide, oxymatrine, matrine, matrine extract, genistein)

2、 Discharge information:

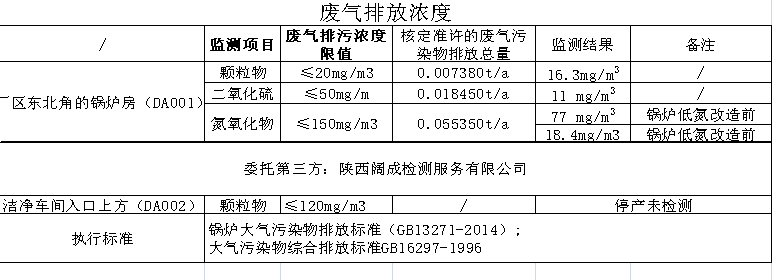

1) Exhaust emission

1. Main pollutants of waste gas: particulate matter, sulfur dioxide, nitrogen oxide.

2. Number and distribution of exhaust gas outlets: 1 boiler room (DA001) located in the northeast corner of the plant area and 1 above the clean workshop entrance (DA002).

3. Exhaust emission concentration

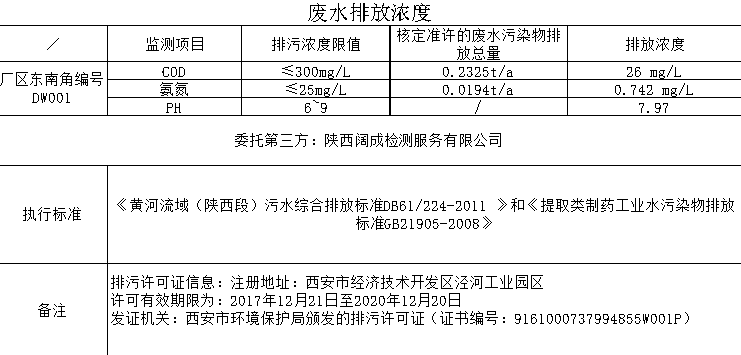

)Wastewater discharge concentration:

1. Main pollutants of wastewater: COD, ammonia nitrogen, PH

2. Discharge mode: intermittent discharge, stable flow during discharge

3. Quantity of wastewater discharge outlet: 1 (No. DW001)

4. Location of discharge outlet: located in the southeast corner of the plant

3、 Conditions of pollutant treatment facilities:

Our company has a set of automatic sewage treatment unit, which is used to treat daily production and domestic sewage in the plant. The designed treatment capacity is 7 tons/day, and the sewage treatment method used is UASB+biological contact oxidation method. The annual operation time is about 300 days, and the annual sewage treatment capacity in 2017 is about 1340 tons.

In 2018, a set of organic waste gas collection and treatment device was equipped with a designed daily waste gas treatment capacity of 6000 m3/h. This set of facilities was constructed by Shaanxi Ruipu Environmental Protection Technology Co., Ltd. and has passed environmental protection acceptance. Through trial operation verification, this group of facilities operates normally and can meet the current production needs of our plant.

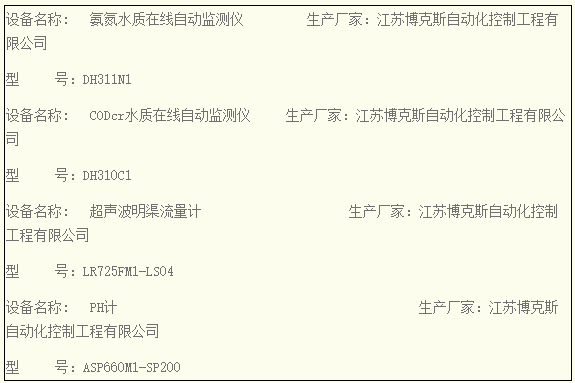

Water quality online monitoring: In January 2019, our factory equipped and installed a complete set of water quality online monitoring equipment, which passed the acceptance and has been filed with the provincial environmental protection bureau for networking.

Because our plant is temporarily in the shutdown state, the competent environmental protection department has made an application for online monitoring equipment shutdown, and the equipment unit has been in the shutdown state, so there is no online monitoring data to be publicized for the time being.

4、 Environmental assessment and environmental acceptance:

Our factory is located in Jinghe Industrial Park, Gaoling District, covering an area of 15 mu. He has been engaged in the pharmaceutical manufacturing industry for more than ten years and has a production line for the preparation of natural active ingredients. This production line was completed in 2002 (GJF [2001] No. 79). In September 2003, the environmental impact assessment was completed, and the approval of Gaoling County Environmental Protection Bureau was obtained on October 23, 2003. In September 2004, the construction of our comprehensive sewage treatment unit was completed, and then an application for acceptance of the construction of environmental protection and treatment facilities was submitted to the Environmental Protection Bureau of Gaoling County in writing. On September 18, 2004, it was accepted by the Environmental Protection Bureau of Gaoling County (GHYZ [2004] No. 90) and officially put into production.

5、 Emergency drill

Shaanxi Dahe Pharmaceutical Co., Ltd. has a set of internally revised Emergency Plan for Environmental Emergencies

Emergency drill for chemical reagent leakage:

Our factory is a manufacturer of crude drugs extracted from traditional Chinese medicine. The alkaline waste liquid in the production process is entrusted to the third party with environmental protection qualification "Shaanxi Hongen Environmental Protection Technology Co., Ltd." for harmless disposal as hazardous waste. There is no staff dormitory and canteen in our factory. The company will provide a certain amount of accommodation allowance, and the accommodation problems of employees will be solved by themselves outside the factory. Therefore, the sewage of our plant is mainly composed of toilet sewage and equipment cleaning sewage, and the drainage volume is not large. All the sewage generated in the plant will enter the sewage treatment station in the plant for treatment, and then discharge up to the standard (the annual average water consumption is about 3000 tons).

Some chemical reagents we will use in the production process and all liquid organic reagents are recycled. If chemical reagents leak, it will cause environmental pollution and even fire.

Drill steps:

The workers found that there was a leakage of liquid chemical reagents in the warehouse.

The workers who found the accident immediately informed other on-site personnel and went to inform the factory director.

The factory director immediately rushed to the site to observe whether there was an open fire, understand what the leaked material was, and immediately ordered the production personnel to cut off the power and fire source, and ordered the redundant personnel to leave the leakage point. At the same time, organize safety personnel to wear gas masks, rubber gloves and rain boots. Take the shovel and dig the sand in the sandbox at the door of the warehouse to block the leaked chemicals. At the same time, plug the leakage point and collect the leaked liquid into the container. Then wash the ground with clean water, dilute the residual organic solvent, and reduce the environmental safety risk.

The factory director arranges the laboratory technician to carry out the sewage sampling at the main sewage discharge outlet, and tests it to confirm whether the water quality is abnormal, and reports it to the environmental protection department for filing.

Since the establishment of Shaanxi Dahe Pharmaceutical Co., Ltd. in 2002, there has been no environmental pollution accident.

6、 Other public information

The daily self-monitoring of pollutants will be carried out at the main discharge outlet, and the data will be uploaded to the provincial pollution source environment information platform. At the beginning of each year, the self-monitoring plan of the current year and the self-monitoring report of the previous year will be published here.

On the platform of the national emission permit information disclosure system, the monthly, quarterly and annual reports are carried out on schedule, and the self-monitoring pollutant emission data are published.

Every year, the generation and disposal of hazardous waste are registered in the provincial solid waste management information system in real time, and the annual hazardous waste transfer plan is declared on the platform.

Shaanxi The River Pharmaceutical Co.,Ltd.

2019/5/30